The competitive landscape of the Chinese automotive wiring harness industry

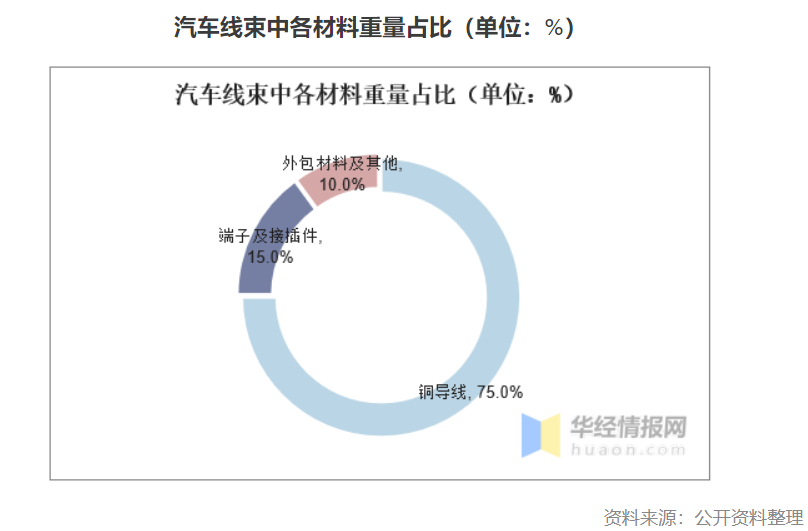

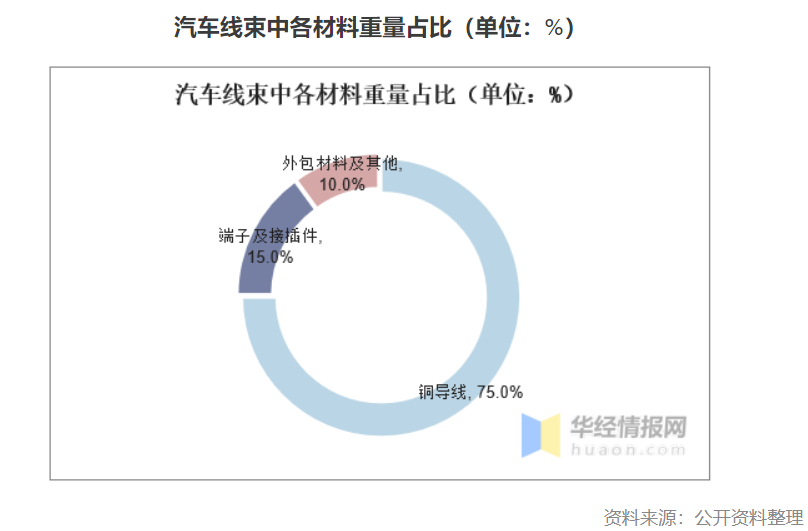

As an important component of the whole vehicle, automotive wiring harnesses account for 2% of the total weight of the vehicle. Furthermore, with the increase in electronic devices in cars, the importance of lightweight wiring harnesses for reducing energy consumption in each vehicle continues to increase. The weight of copper wire in automotive wiring harnesses accounts for 75%, and is the main lightweight direction.

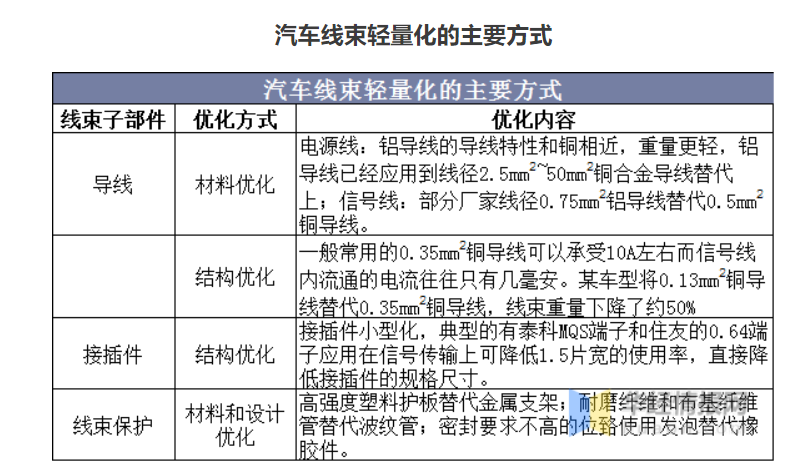

The lightweight of automotive wiring harnesses mainly includes material lightweight, structural lightweight, and layout optimization. 1) Material optimization, aluminum wires have similar conductivity characteristics to copper, are lighter in weight, and are increasingly being used in power and signal wires; 2) Structural optimization, using ultra-fine copper wires for signal wires, which can reduce the weight of the wiring harness by 50% while ensuring current conduction; 3) Layout optimization: Bosch, a top supplier of automotive components, and BMW, a top vehicle manufacturer, have proposed a vision for domain control architecture and power distribution architecture. Tesla, a leading new energy vehicle manufacturer, has achieved mass production matching of domain control architecture and power distribution architecture on Model 3.